ASIC

Application Specific Integrated Circuit. An ASIC is a custom IC, which means it is not a standard product such as a microprocessor, memory, standard logic chip or generic component which might be available from several or many different manufacturers. It will often add functionality not available from a standard product, or combine the functions of many standard products at a lower total price.

You might make an ASIC because:

- You need a chip that isn’t available off-the-shelf,

- You can save money by merging a lot of components into one,

- Recently, for fun!

If your design only needs digital logic, you might be able to use an FPGA. An advantage of ASICs is that they can combine digital and analogue circuits together in one chip. A disadvantage is that errors often cannot be fixed afterwards, hence the heavy use of verification.

Big semiconductor companies produce millions of chips, which can offset the large costs related to the masks. For example, a full maskset for the 130nm process at the Skywater foundry costs about $200k.

Until recently, an additional cost was the license fee for the ASIC software tools. Now we have the open source tools like OpenLane that have opened the door to experimentation and learning.

Here’s a picture from magic showing a layout of my VGA clock

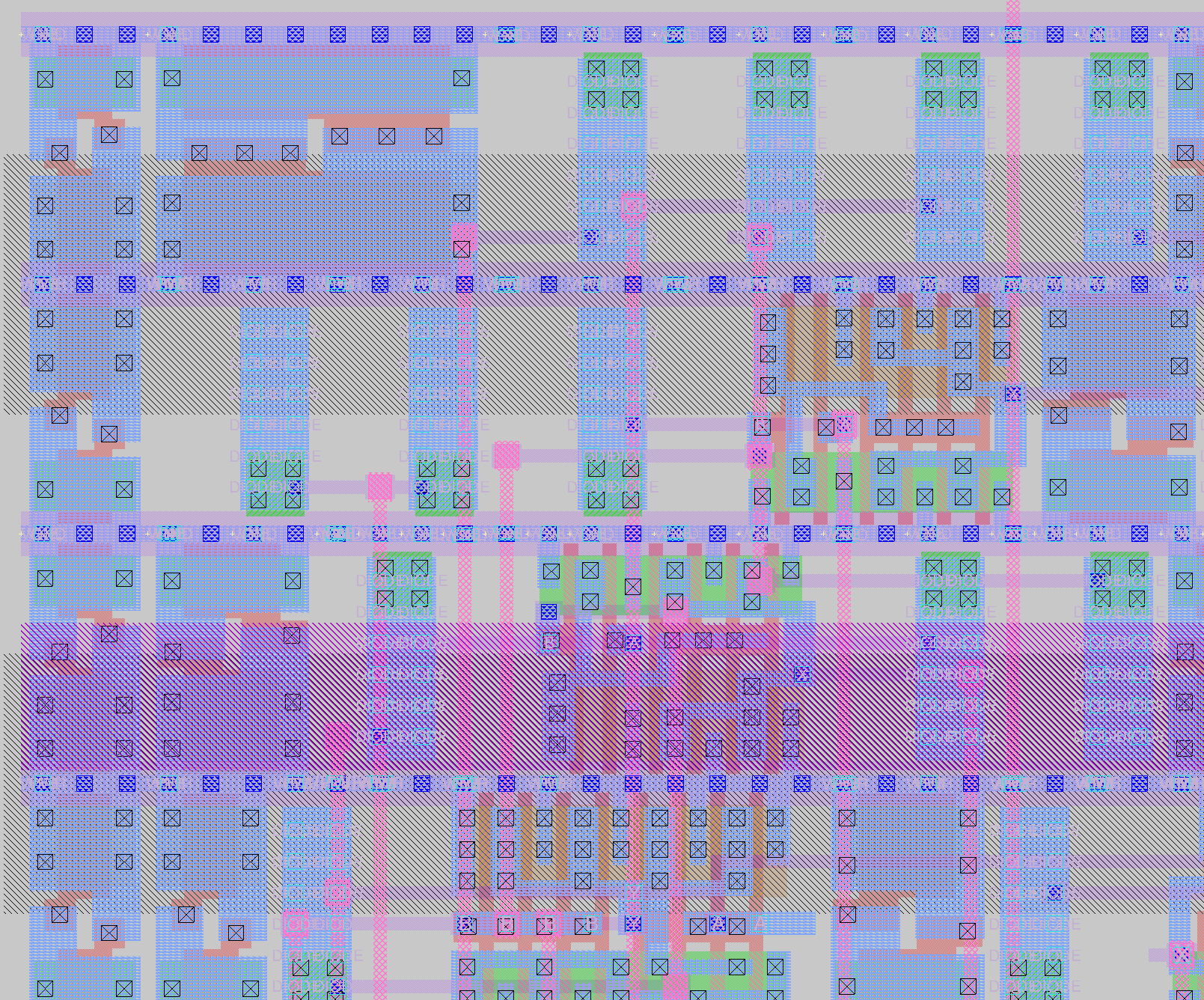

And a zoom, more clearly showing the standard cells

Course feedback

It is immensely helpful to have somebody who has gone through everything and know if something is not documented. You can read all day but you will not get the same out of it, so that was tremendously helpful.

Tommy Thorn (digital course)